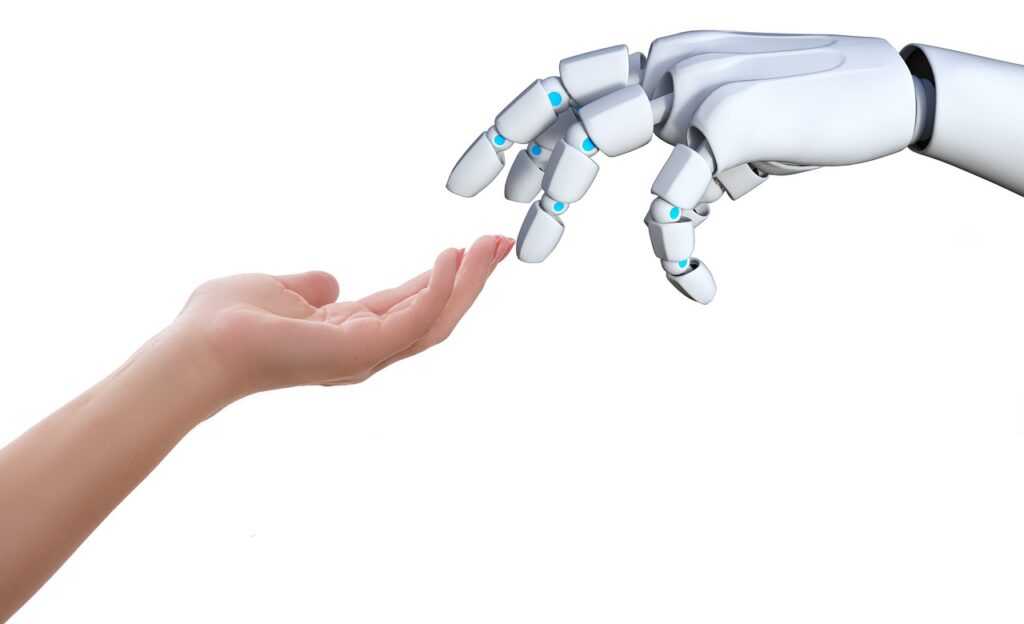

Smarter Collaboration, Not Just Automation

Robots aren’t replacing workers they’re becoming teammates. The future of industry isn’t about cutting humans out of the process. It’s about building machines that make human work safer, faster, and more focused. The keyword here is enhancement, not elimination.

Real time communication is pushing this forward. Workers can now command machines on the fly adjusting behavior, pace, or task with a tap of a wearable or a spoken instruction. It’s not sci fi. It’s on the factory floor today.

Enter co bots: collaborative robots built to work side by side with people. They don’t run on isolated lines; they adapt, learn, and align with human effort. That changes everything from how factories are designed to how teams operate. No more siloed automation. The new model centers on shared space and shared goals. Less about who does what. More about what gets done together.

Machine Vision Is the Game Changer

Robots don’t just move parts anymore they see. And that small shift is making a huge impact. Visual recognition, powered by advanced cameras and AI, now allows robots to identify objects, read labels, track movements, and make real time decisions. This isn’t just about efficiency; it’s about precision. In a manufacturing line or warehouse floor, a bot that can visually inspect and adjust mid task is one that can keep pace with unpredictable demands.

Safety is another game winning play. With machine vision, robots are getting better at recognizing human presence understanding when a person enters a shared space, slowing or stopping to avoid collisions, and discerning body posture to interpret intent. It’s not about making robots polite. It’s about making them safer and smarter collaborators.

Unpredictable environments used to throw automation out of sync. Not anymore. Machine vision enables situational awareness, letting robots adapt on the fly. A dropped item, a shifted assembly piece, poor lighting none of it derails a visually enabled system like it used to. Instead, the robot recalibrates and moves on. Fewer halts. More resilience.

For a deeper breakdown of how this tech is rebuilding the frontier of industrial robotics, check out this piece on machine vision in robotics.

Adaptive Learning on the Job

Robots aren’t just executing tasks they’re starting to learn how we move, decide, and adapt. Thanks to advances in machine learning and sensor integration, modern industrial robots can observe a human performing a task and begin mimicking key actions with a surprising degree of accuracy. It’s not perfect out of the gate, but it doesn’t need to be. What matters is the feedback loop.

Every time a robot gets something slightly wrong, it adjusts based on data it’s fed in real time. The more interaction, the faster it picks up patterns. Over hours not weeks an intelligent system can go from basic imitation to full task execution, tailored to a specific working style or environment. Think hand over hand guidance at first, then supervised repetition, then autonomy.

This isn’t some futuristic promise it’s already happening in warehouses, labs, and even surgical prep. The goal isn’t for robots to replace skilled workers. It’s to offload repetitive bulk while learning the nuance of human judgment through observation and iteration. The faster they learn, the faster teams scale.

The Hidden Shift: Interface Design

Not long ago, programming a robot meant writing lines of code or feeding it detailed scripts. Now? You can just tell it what to do. Natural language processing has cracked open a door to more intuitive robotic control. Think commands like “Pick up the red box” or “Sort these by type” no compiling, no coding wizardry required. It shrinks the learning curve and opens robotics to more teams across the shop floor.

Gesture controls are stepping in too, letting operators guide machines with motion rather than keyboards. And wearable tech smart gloves, haptic bands are bridging the physical digital gap. The signal is clear: robots are being redesigned to understand people, not the other way around.

This shift matters because it removes the old gatekeepers. No engineering degree? No problem. Making robots usable for line workers, shift managers, or warehouse staff isn’t just convenience it’s strategy. More people can contribute. More ideas get tested. And the pace of innovation picks up. In short, human robot collaboration only works when the tech speaks a ‘human’ language.

Risk, Regulation, and the Human Element

Ethical and Legal Responsibilities in Shared Workspaces

As human robot collaboration becomes more common, ethical and regulatory questions are moving to the forefront. Employers must now consider how to protect both human workers and robotic systems in shared environments.

Key considerations include:

Defining responsibility in the event of a system error or accident

Ensuring data privacy when robots collect and process workplace information

Maintaining transparency around algorithmic decision making

These new challenges require cross disciplinary collaboration between engineers, ethicists, regulators, and labor organizations.

Rewriting Safety Protocols

Traditional safety protocols aren’t built for environments where humans and robots interact in real time. Industries are now re engineering workflows and physical spaces to prioritize:

Proximity sensing and real time human detection

Dynamic risk assessments based on activity and context

Built in pause or override controls accessible to workers

In many facilities, safety zones are being redefined not to limit robots, but to enable shared spaces that adapt to both human presence and machine function.

Judgment Calls Still Belong to Humans

Despite advancements in robotics, humans remain essential in making the nuanced decisions that require context and emotional intelligence. Robots are not replacing human insight they’re augmenting human potential.

Robots can execute tasks, but humans determine purpose and priority

Decision making in unexpected or morally complex situations stays with people

The best results come from robots amplifying not replacing human action

Outlook: Partnering for Progress

The next three to five years will be defined less by robots taking over and more by how well humans and robots can work as a team. Think fewer sci fi takeovers, more streamlined shifts on the factory floor. Co working with machines is no longer a future concept it’s the new baseline, and industries that lean into this partnership are already seeing gains in efficiency, safety, and adaptability.

As robotics gets smarter thanks to improvements in machine vision, adaptive learning, and real time responsiveness the pressure shifts to the human side. Workers will need new skills. Not coding mastery or engineering degrees, necessarily, but practical fluency in operating, communicating with, and troubleshooting smart machines. Upskilling doesn’t mean starting over. It means layering new competencies onto existing know how.

For companies, the challenge is clear: make training fast, focused, and accessible. For workers, it’s an opportunity not a threat. The ones who can balance instinct with machine logic will own the next stage of industrial evolution.

Want to understand what’s powering this shift? Read about machine vision in robotics.

Lorissa Ollvain is a tech author and co-founder of gfxrobotection with expertise in AI, digital protection, and smart technology solutions. She is dedicated to making advanced technology accessible through informative, user-focused content.

Lorissa Ollvain is a tech author and co-founder of gfxrobotection with expertise in AI, digital protection, and smart technology solutions. She is dedicated to making advanced technology accessible through informative, user-focused content.